High Quality Fluidized bed Quick Freezing for frozen french fries from first cold chain

- Price

- US $60000-200000

- Model

- FSLD

- MOQ

- 1 set

Item specifics

- Refrigerant

- Freon

- Structure

- Assembled

- Suitable for

- Factory

- Refrigeration System

- Brand Compressor Unit

- Size

- Customized

- Use Nature

- Production

- Usage

- Vegetable & Fruit

- Freezer Body Material

- 304 Stainless Steel

- Specification

- CE ISO9001

- Transport Package

- Seaworthy Plywood Case

Review

Description

Fluidized Bed Quick Freezing Main Features

1) Suitable for fluidized IQF frozen processing for green peas or fruits and vegetables slices, dices etc.

2) Frequency converters for belt conveying and also fan blowers which assure flexibility during the production even with the most difficult products.

3) Extraordinary freezing efficiency is guaranteed by the extremely efficient evaporator, optimized design and quality finishing.

4) Easy access to all freezer parts, easy handling of maintenance and cleaning operations.

5) Stainless steel wire mesh belt, which is the most reliable solution by now, proven performance by users, and universal solution for easier replacement and maintenance all over the world.

6) Superior fluidized IQF function by extra belt hitting system together with the adjustable high pressure centrifugal blower to generate vertical air flows which keep the materials in a fluidized condition during the freezing process.

7) With our high quality stainless steel belt and on position cleaning device for the belt, we can bring the highest sanitation level and easy work for cleaning of our freezer.

FSLD series fluidized bed quick freezing parameters:

Mode | FSLD500 | FSLD1000 | FSLD1500 | FSLD2000 | FSLD3000 |

|---|---|---|---|---|---|

Throughput±10%(kg/h) | 500 | 1000 | 1500 | 2000 | 3000 |

Refrigeration capacity (kw/h) | 90 | 170 | 255 | 320 | 480 |

Freezer room size | 5×4.0×2.9 | 9*4.2*2.9 | 12.5×4.2×2.9 | 15×4.2×2.9 | 19.5×4.2×2.9 |

Exterior size | 7×4.0×2.9 | 11×4.2×2.9 | 14.5×4.2×2.9 | 17×4.2×2.9 | 21.5×4.2×2.9 |

Power(Kw) | 19 | 35.2 | 49.2 | 61.2 | 78 |

In feed temperature | +15℃ | +15℃ | +15℃ | +15℃ | +15℃ |

Out feed temperature | -18℃ | -18℃ | -18℃ | -18℃ | -18℃ |

Inner circulation temperature | -35±2℃ | -35±2℃ | -35±2℃ | -35±2℃ | -35±2℃ |

Frozen time(Min) | 6-30 | 6-30 | 6-30 | 6-30 | 6-30 |

Refrigerant | R717/R404A | R404A/R717 | R404A/R717 | R404A/R717 | R404A/R717 |

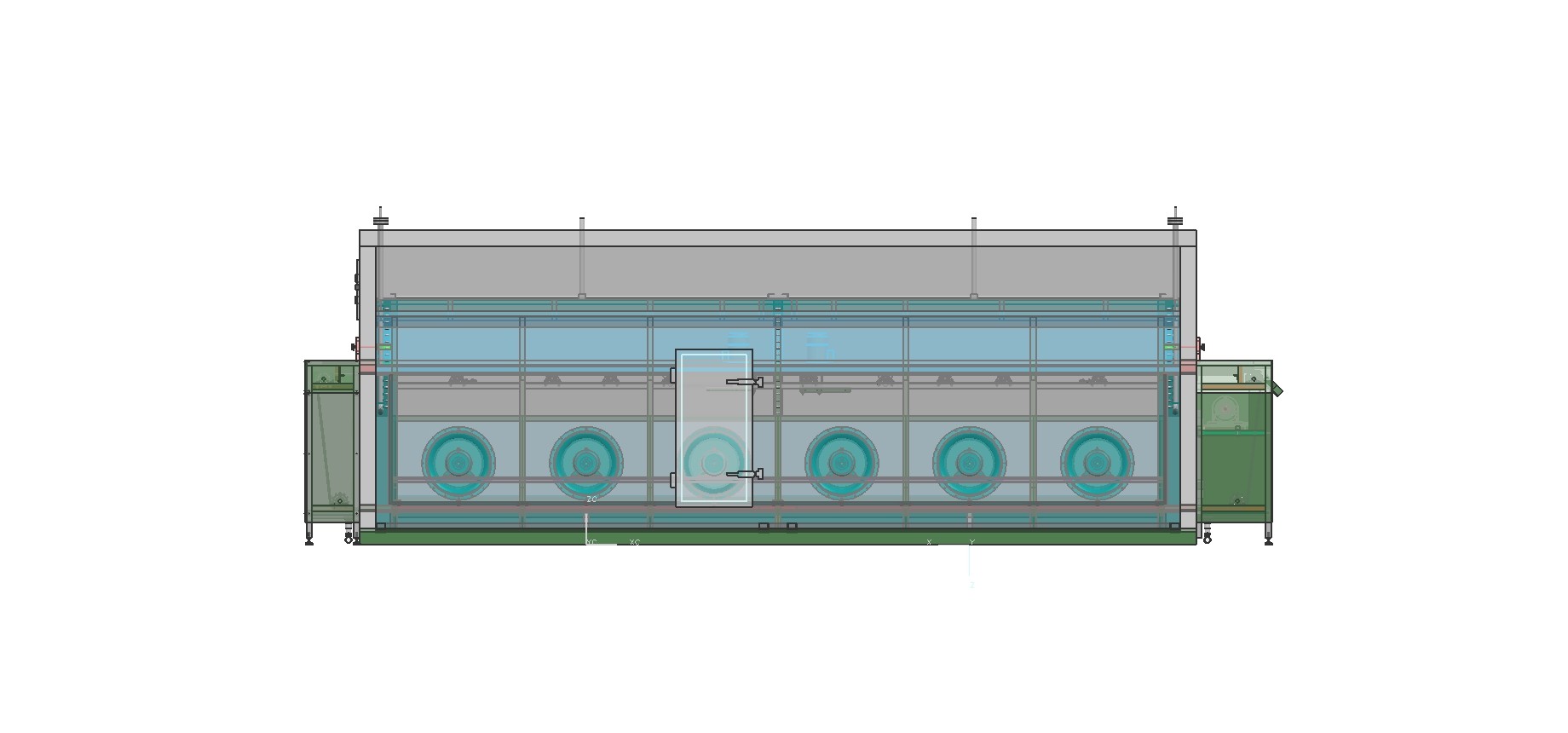

Fluidized bed quick freezing structure diagram

FSLD1000 IQF FREEZER TECHNICAL PARAMETERS

Item | FSLD1000( frozen fries) | |

|---|---|---|

Product | Frozen fries | |

Capacity | 1000kg/h | |

In/Out Temp. | +15℃ to -18℃ | |

Freezer Temp. | -35℃ | |

In/Out Time | 10-50min | |

Refrigerant | R404A | |

Consumption | 170kw | |

Freezing Container Thickness | 150mm | |

Product Height | ≤100mm | |

Belt Width | 1200mm | |

Product Input Conveyor/Output Conveyor | 1000 mm/500mm | |

Diameter Liquid Input/Gas Return Output Pipe | Φ22 mm/Φ57mm*4 | |

Water Input Pressure | ≥3 kg/cm2 | |

Freezer Power | 39 KW | |

Freezer Size(L*W*H) | 11500×4000×2900mm | |

Freezer Body Material | Duplex stainless steel polyurethane insulation board density or 40 kg/m3, the thickness of 150 mm, 304 stainless steel outer plate thickness more than 0.5 mm | |

Main Electric Brand | Schneider(France) | |

Belt and Speed | Food-grade plastic mesh belt; Frequency conversion stepless speed regulation | |

Slide Track Material | Ultrahigh molecular polyethylene material. | |

Internal Structure | All made of 304 Stainless Steel Material, Argon arc welding | |

Evaporator | Effective from large aluminum finned tube set, stainless steel panel stent | |

Fan and Motor | Aluminum alloy stainless steel duct fan low noise and waterproof electric power consumption | |