Excellent Polyurethane foam board mobile cold room for made in china

- Price

- US $25-40

- Model

- Cold storage polyurethane sandwich board

- MOQ

- 50 square meter

Item specifics

- Color

- various kind color

- Structure

- Assembled

- Suitable for

- Factory cold room /storage

- Material

- Rigid polyurethane foam

- Application

- Exterior Wall

- Density

- 40~45kg/m3

- Transport Package

- Sea Worthy Packing

- After-Sales Service

- Assisting Service

Review

Description

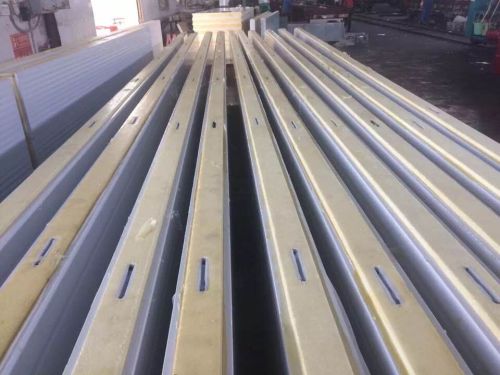

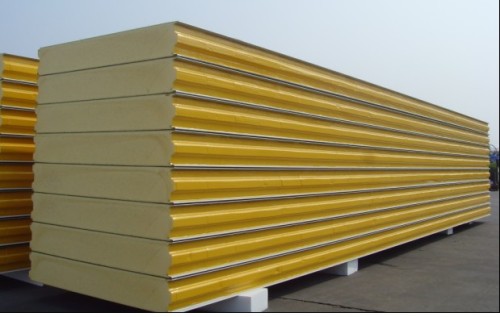

Material used rigid polyurethane or polystyrene foam insulation sandwich, one time high-pressure perfusion molding foam process, can be made in various lengths and specifications. Its characteristics are: "Good insulation performance, lightweight, high strength, corrosion resistant, anti-aging, beautiful appearance."

Specifications

1. Panel width: 960mm, 980mm, 1150mm

2. Thickness: 50, 75, 100, 150, 200 mm

3. Length: According to project and transportation requirement

4. Color: According to project requirement (RAL Color)

6. Variety: H-beam (flat sheet, profiled sheet), matchboard, corrugated sandwich panel

Types are:

Color steel, salinization steel, stainless steel, aluminum embossed.

Product name | Polyurethane (PU) Sandwich Board | ||||

|---|---|---|---|---|---|

Thickness | Upper layer | 0.5-0.8mm | |||

Core material | 75mm, 100mm, 120mm,150mm | ||||

Bottom layer | 0.5-0.8mm | ||||

Effective Width | Standard | 960mm | |||

Other | can be customized | ||||

Length | Customized, less than 12m | ||||

Density | 38-40kg/m3 | ||||

Weight | Up to model | ||||

Color | Generally white, blue, red, green | ||||

Temp tolerance | -120-90℃ | ||||

Fire resistance level | A2 (incombustible) | ||||

Surface profile | Flat,corrugated, small wave | ||||

Compression bearing | ≥0.2Mpa | ||||

Material | Upper layer | PPGI (prepainted galvanised steel) color steel sheet | |||

Inner layer | PU foam (injected, not glued) | ||||

Bottom layer | PPGI (prepainted galvanised steel) color steel sheet | ||||

Parts | Eccentric hook used for connection of panel | ||||

Film covering for protecting the surface layer | |||||

Characteristics | Heat insulation energy-saving | 100mm width can keep temp at 0℃ (suit for fresh keeping) | |||

150mm width can keep temp at -18℃ (suit for cold storage) | |||||

200mm width can keep temp at -38℃ (suit for freezing) | |||||

Water resistance and sound proof | |||||

Weather proofing | |||||

Light weight compared to traditional stone or plaster panel | |||||

Fire retardant level: B | |||||

Safe and green,good appearance,without formaldehyde | |||||

High strength and bending resistance | |||||

Easy quick installation and dismantling | |||||

Lifespan | can reach 15-20 years | ||||

Main application | Can be used for wall,roof,floor and partition of cold storage, mobile house, industrial plants, warehouses, supermarkets, hospitals, stadiums, activities room and reconstruction residence, villa, commercial building, remodeling of old structures, heat insulation fire places, airport, etc | ||||