The Impingement Freezer: Revolutionizing Shrimp Freezing for Optimal Efficiency

Impingement freezer Introduction:

Shrimp lovers around the world can now rejoice as the impingement freezer enters the scene, offering a groundbreaking solution to freeze shrimp effectively, efficiently, and without compromising on quality. This innovative technology not only ensures superior freezing capabilities but also takes up less space, making it an ideal choice for seafood businesses. In this article, we will explore the reasons why choosing an impact freezer can have a significant impact on the shrimp freezing process.

1. Unparalleled Freezing Efficiency:

The impact freezer sets a new standard in freezing technology by rapidly freezing shrimp to preserve their freshness and taste. This cutting-edge equipment utilizes advanced freezing techniques that ensure the shrimp are frozen quickly and evenly, locking in their natural flavors and textures. Unlike traditional freezing methods, the impact freezer minimizes the formation of ice crystals, resulting in superior product quality and reduced moisture loss.

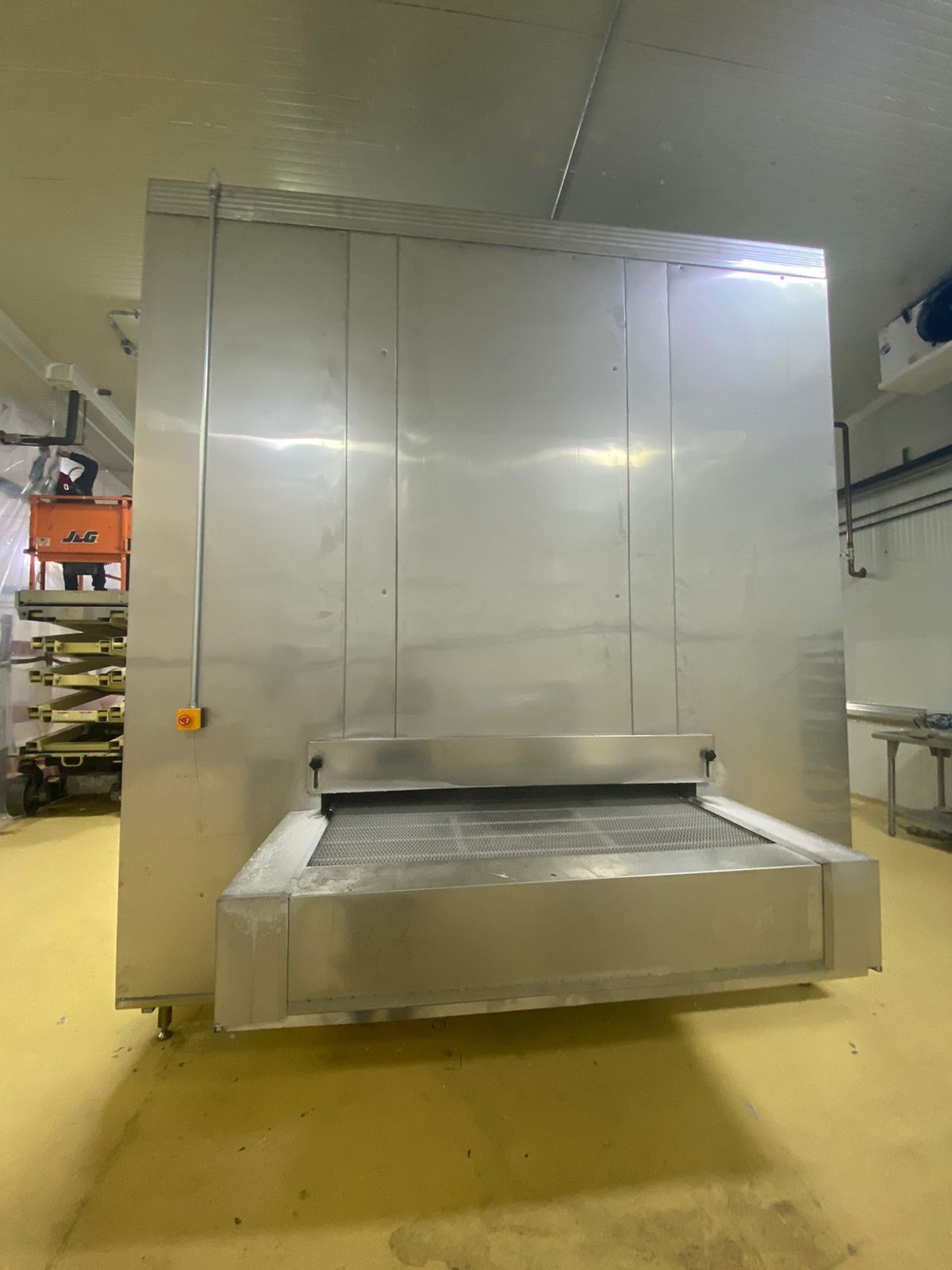

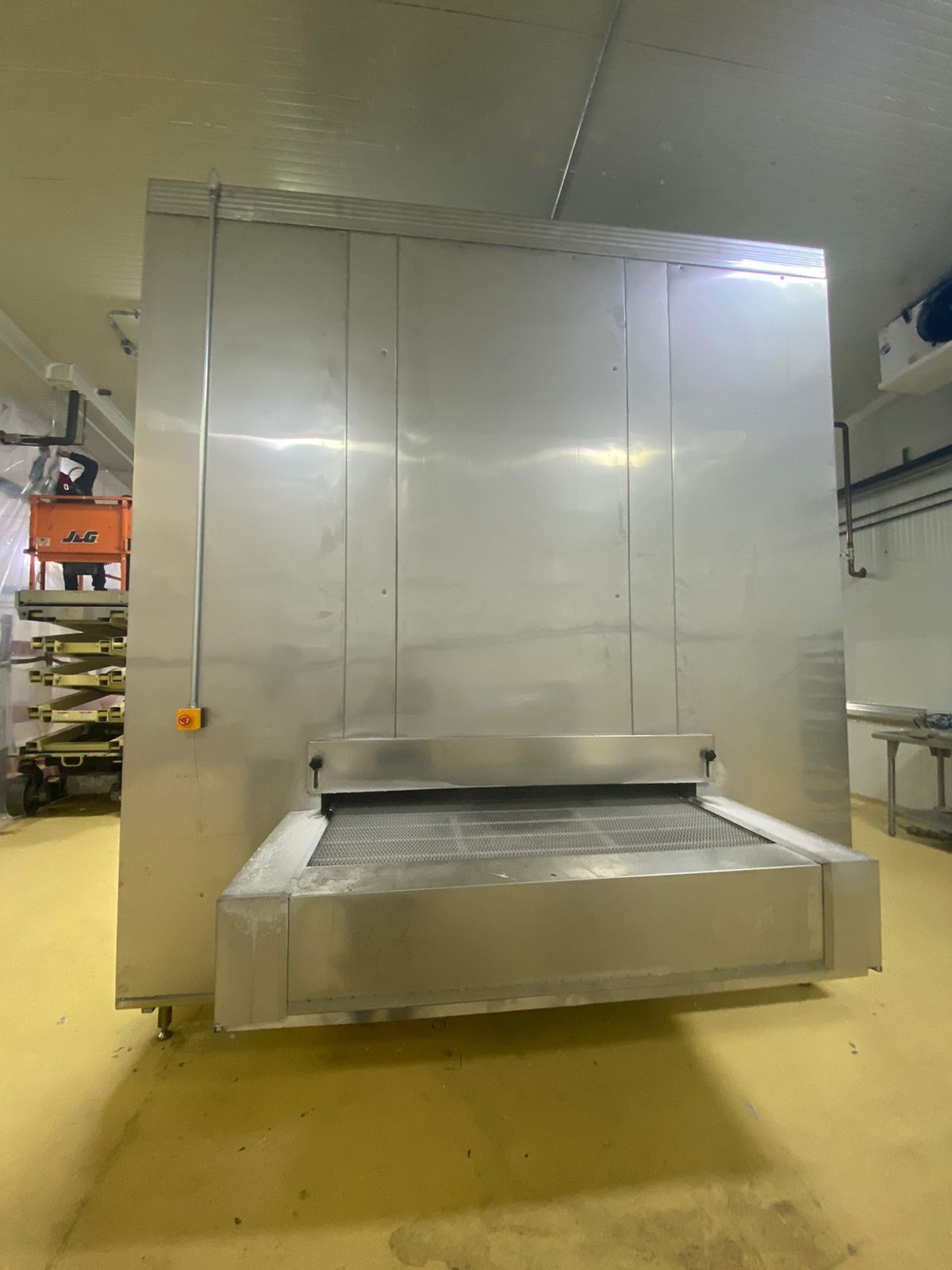

2. Space-Saving Design:

One of the key advantages of an impact freezer is its compact design, which allows businesses to optimize their storage space efficiently. With traditional freezing methods, large freezer rooms or bulky equipment are often required to accommodate the freezing process. However, the impact freezer's innovative design takes up significantly less space, enabling seafood businesses to maximize their storage capacity and streamline their operations.

3. Enhanced Productivity:

The impact freezer's rapid freezing capabilities not only improve the quality of the shrimp but also enhance overall productivity. With shorter freezing cycles, businesses can increase their processing capacity, leading to higher production volumes. This not only meets the growing demand for frozen shrimp but also allows businesses to reduce costs associated with storage and transportation.

4. Preserving Nutritional Value:

Shrimp are not only renowned for their delectable taste but also for their nutritional value. The impact freezer recognizes the importance of preserving the nutritional content of shrimp during the freezing process. By freezing shrimp quickly and efficiently, the impact freezer helps retain essential nutrients, vitamins, and minerals, ensuring that consumers can enjoy a healthy and delicious meal.

5. Cost-Effective Solution:

Investing in an impact freezer proves to be a cost-effective solution for seafood businesses in the long run. With its efficient freezing capabilities and increased productivity, businesses can reduce energy consumption, minimize product waste, and optimize storage space. Additionally, the impact freezer's durable construction and low maintenance requirements contribute to its cost-effectiveness, providing businesses with a reliable freezing solution that yields significant returns on investment.

Conclusion:

The impact freezer has revolutionized the shrimp freezing industry, offering businesses an innovative solution that combines superior freezing efficiency, space-saving design, and enhanced productivity. By choosing an impact freezer, seafood businesses can ensure that their frozen shrimp products retain their freshness, taste, and nutritional value, while also optimizing their storage space and reducing costs. Embrace the impact freezer and experience the transformative power it brings to the world of shrimp freezing.

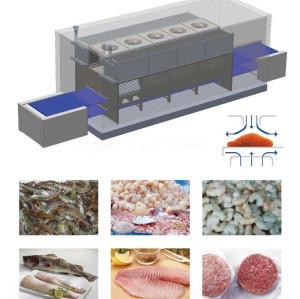

FIW750 Impingement Freezer for Shrimp Freeze

Item | FIW750( Frozen shrimp ) |

|---|

Product | Frozen shrimp |

Capacity | 750kg/h |

In/Out Temp. | +25℃ to -18℃ |

Freezer Temp. | -40℃ |

In/Out Time | 15-75min |

Refrigerant | R717 |

Consumption | 150kw |

Freezing Container Thickness | 150mm |

Product Height | ≤100mm |

Belt Width | 1800mm |

Product Input Conveyor/Output Conveyor | 750 mm |

Water Input Pressure | ≥3 kg/cm2 |

Freezer Power | 46.2KW |

Freezer Size(L*W*H) | 13000×4200×3200mm |

Freezer Body Material | Duplex stainless steel polyurethane insulation board density or 40 kg/m3, the thickness of 150 mm, 304 stainless steel outer plate thickness more than 0.8 mm |

Main Electric Brand | Schneider(France) |

Belt and Speed | Food-grade stainless steel mesh belt; Frequency conversion stepless speed regulation |

Slide Track Material | Ultrahigh molecular polyethylene material. |

Internal Structure | All made of 304 Stainless Steel Material, Argon arc welding |

Evaporator | Effective from large aluminum finned tube set, stainless steel panel stent |

Fan and Motor | Aluminum alloy stainless steel duct fan low noise and waterproof electric power consumption |