BQF quick freezing /blast freezer machinery according to client request to design from first cold chain company

- Price

- US $50000-100000

- Model

- FPF

- MOQ

- 1 set

Item specifics

- Refrigerant

- Freon

- Structure

- Assembled

- Suitable for

- Factory

- Refrigeration System

- Brand Compressor Unit

- Size

- Customized

- Use Nature

- Production

- Usage

- Vegetable & Fruit

- Freezer Body Material

- 304 Stainless Steel

- Specification

- CE ISO9001

- Transport Package

- Seaworthy Plywood Case

Review

Description

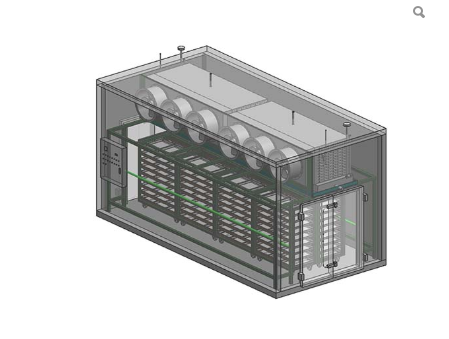

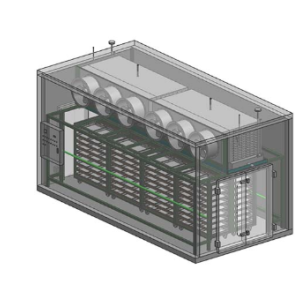

The temperature of the BQF quick freezing is generally -25°C to -35°C, and it is mainly used for low-temperature quick-freezing of food, medicine, medicinal materials, chemical raw materials and other items. The requirements of the general quick-freezing warehouse are that the cooled food should be quick-frozen immediately; the food should pass through the largest ice crystal area in a very short time; the average temperature of the food after freezing should be -18°C.

Quick-freezing warehouses generally require small storage capacity and large cooling capacity. Different freezing time, different product prices will have a big difference.

The design features and advantages of the first cold chain blast freezer :

1. Use the most advanced refrigeration technology and insulation board manufacturing technology.

2. The thermal insulation board of the blast freezer has good heat insulation performance, and can reach the set temperature quickly, saving electricity costs.

3. The thickness of the storage board is generally 150mm or 200mm. The board is filled with polyurethane insulation material. The double sides are plastic-coated color steel plate or stainless steel plate. The surface of the color steel plate is processed into an invisible groove. It is light in weight, high in strength and good in heat insulation performance , Corrosion resistance, anti-aging, the warehouse board is easy and quick to assemble, and it is one of the best materials for cold storage insulation.

4. The blast freezer adopts advanced microcomputer control system and advanced control method. The liquid crystal displays the temperature in the warehouse, start-up time, melting time, fan delay time, alarm indication and various technical parameters. The operation is simple and the user is very convenient to use.

5. The main components of the blast freezer are all imported international famous brands, which ensure that the quick-freezing warehouse has reasonable configuration, stable operation, good thermal insulation performance, low consumption and high energy, and excellent quality.

6. The dimensions, storage temperature, location of the unit, opening of the storage door, layout in the storage, etc. of the quick-freezing storage can all be designed and customized according to the specific requirements of the user. To meet the needs of users to the greatest extent.