Full automatic fluidized bed IQF freezer FSLD1000 for Frozen French Fries Processing line for fries

- Price

- US $20000-150000

- Model

- FSLD1000

- MOQ

- 1 set

Item specifics

- Material

- 304 stainless steel

- Power source

- Electric

- Size

- Customized

- Voltage

- 380V

- Specification

- CE ISO9001

- Transport Package

- Seaworthy Plywood Case

Review

Description

Frozen fries processing line introduce :

♡ Various choices. We supply100~2000 kg/h for customers.

♡ Longer service life. Stainless steel to guarantee a longer service life for processing larger quantity of French fries.

♡ High efficiency and energy saving. Excellent quality and Low oil consumption.

♡ Easy operation and multifunctional usage.

♡ Comparative price and high rate of profitable return.

Brief Introduction of French Fries Production Line

♡ All the machines in the production line are made of stainless steel 304

♡ Electricity power requirement is 380V/50Hz/three-phase.

♡ The cutting machine can cut the potato sticks of thickness 2-10mm, it is adjustable.

Storage Guide for Frozen French Fries

☞ At - 18°C until date printed on the packaging.

☞ At - 12°C 1 month.

☞ At - 6 °C 1 week.

☞ Once defrosted do not refreeze

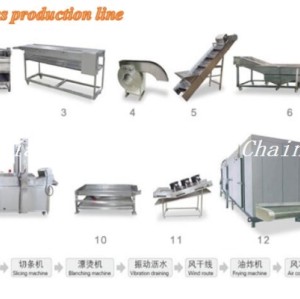

Frozen fries processing line Main parts list

Name | Product name | Introduction |

|---|---|---|

1 | Feed machine | Mainly used for the delivery of potatoes, raw material |

2 | Cleaning and peeling machine | Washing and peeling the potatoes; It is brush washing peeling machine |

3 | Picking line | Mainly used for workers in the transport process of picking the unqualified materials |

4 | Lifting machine | The device is mainly used for the delivery of potato. |

5 | French fries cutter | Cut the potatoes into different sizes of French fries This machine is used to cut potatoes into sticks. it can cut potato, sweet potato, taro into sticks. It is smooth in surface and cut in fast speed. Easy to wash and easy to operate. Save labor and cost. |

6.7 | Washing Blanching machine | Washing time is 30-40s; Washing process is for washing off the potato starch on the French fries which can keep it from fall in the oil and keep long-use life for the frying machine. At the same time, the French fries is totally immersed in water which can keep it from enzymatic-oxydative browning; it can wash off the sugar on the surface of the chips then it can keep the oil from turning bad and keep a long using life. |

Blanching is a necessary procedure. After washing, the potato sticks go into the blanching machine which is about 65-90℃ hot water. It can destroy the enzyme activity, and improve the organizational structure. | ||

8 | Air cooling dehydration machine | After removal of the hot french fries, on the surface of excess water |

9 | Frying machine | Frying the French fries; oil or oil-water structure; electric, gas, diesel ; automatic feeding and discharging |

10 | Air cooling dehydration machine | After removal of the hot french fries, on the surface of excess water |

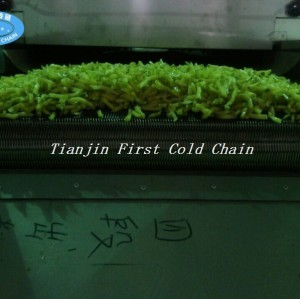

11 | Freezing | IQF freezer |

12 | Packing machine | Pack the French fries into different bags |