Tunnel Freezer for meat from 100kg/h to 1500kg/h in China first cold chain

- Price

- US $30000-180000

- Model

- FSW

- MOQ

- 1 set

Item specifics

- Refrigerant

- Freon

- Structure

- Assembled

- Suitable for

- Factory

- Refrigeration System

- Brand Compressor Unit

- Size

- Customized

- Use Nature

- Production

- Usage

- Food

- Freezer Body Material

- 304 Stainless Steel

- Specification

- CE ISO9001

- Transport Package

- Seaworthy Plywood Case

Review

Description

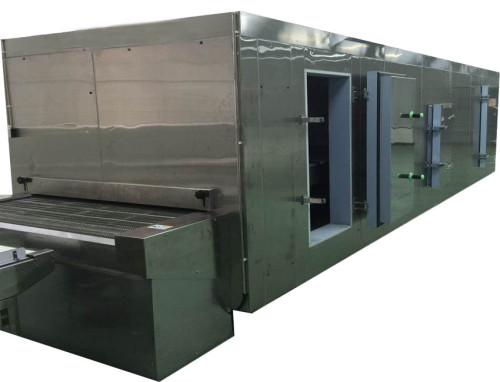

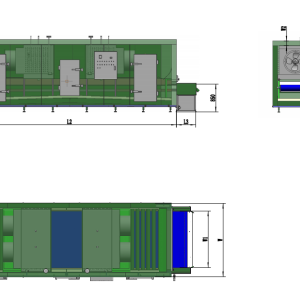

Tunnel Freezer Product Description

Main applications of tunnel freezer

The tunnel freezer is widely used in the IQF and frozen in the trays for many different food products. It is suitable for various prepared food products such as dumpling, fish ball and snack food etc., also very popular for poultry, meat, aquatic and seafood products. It is very flexible for processing, it can freeze products directly on the belt, also available when you need to freeze the products in trays or after packing.

Main features of tunnel freezer:

The Tunnel Freezer is with compact structure. It can realize the continuous high quality IQF frozen before or after packing in a very energy saving way. By multi-direction air flow, it ensures high quality individual quick freezing result. The processing speed adopt frequency control to meet the needs of processing various frozen products. The wide stainless steel mesh belt or stainless steel plate belt is used for high sanitation level and long steady working time.

The evaporator is made of aluminum coils and fins, variable fins gap to get the optimum result of the heat exchange efficiency. Main frames and parts are all made of stainless steel and food level materials, which comply with the food hygienic standards.

On position cleaning device is provided to clean the residues on the conveying belt. Humanized designs making the operation and maintenance much easier for you.

The tunnel freezer is widely used in the IQF and frozen in the trays for many different food products. It is suitable for various prepared food products such as dumpling, fish ball and snack food etc., also very popular for poultry, meat, aquatic and seafood products. It is very flexible for processing, it can freeze products directly on the belt, also available when you need to freeze the products in trays or after packing.

Main features of tunnel freezer:

The Tunnel Freezer is with compact structure. It can realize the continuous high quality IQF frozen before or after packing in a very energy saving way. By multi-direction air flow, it ensures high quality individual quick freezing result. The processing speed adopt frequency control to meet the needs of processing various frozen products. The wide stainless steel mesh belt or stainless steel plate belt is used for high sanitation level and long steady working time.

The evaporator is made of aluminum coils and fins, variable fins gap to get the optimum result of the heat exchange efficiency. Main frames and parts are all made of stainless steel and food level materials, which comply with the food hygienic standards.

On position cleaning device is provided to clean the residues on the conveying belt. Humanized designs making the operation and maintenance much easier for you.