What are the installation standards of fluorine cooling pipe in cold storage?

- Share

- From

- First Cold Chain

- publisher

- sunny

- Issue Time

- Apr 2,2022

Summary

Freon cooling pipe installation is generally used for small cold storage installation, if need to build small fruit and vegetable storage cold storage can be used, because of the lighter weight

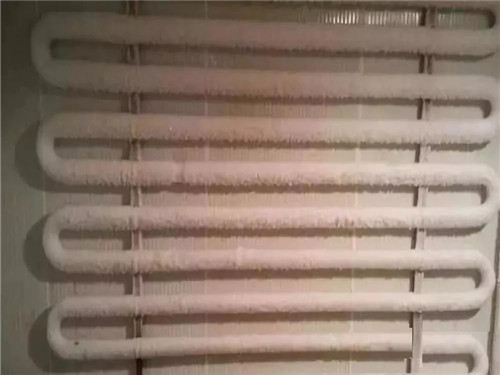

Fluorine cooling pipe installation is generally used for small cold storage installation, if need to build small fruit and vegetable storage cold storage can be used, because of the lighter weight, easy to use manual or with the help of hoist according to construction drawings for hoisting. After lifting the level of certification can be fixed in the pre-buried point, on the support.

1. The main results are as follows:

(1) the fluor cooling pipe is usually made of red copper pipe, which is made into serpentine coil pipe according to the construction drawing, and the maximum length of each pass shall not exceed 50m, and the copper pipe of the same diameter cannot be directly welded to each other when it is rewelded. The tube expander was used to expand the tube on one of the copper tubes and then another copper tube was inserted into the tube (or straight through) and then welded by silver or brazing. When welding purple copper pipe with different diameter, the corresponding straight-through, three-way, four-way copper pipe hoop should be purchased.

(2)The tube code made of circular steel (Q235 material) is fixed on 30 * 30 *3 angle steel after manufacture of fluorine cooled serpentine coil.

2. Sewerage, pressure test, leak collection and vacuum test

3. The fluorine cooling drainage pipe (or fluorine cooling snake coil) uses nitrogen to discharge and test the pressure. The leakage detection can be done first by soap-water method for repair welding. A small amount of Freon is infused into the pipe, and it rises to 1.2MPa.