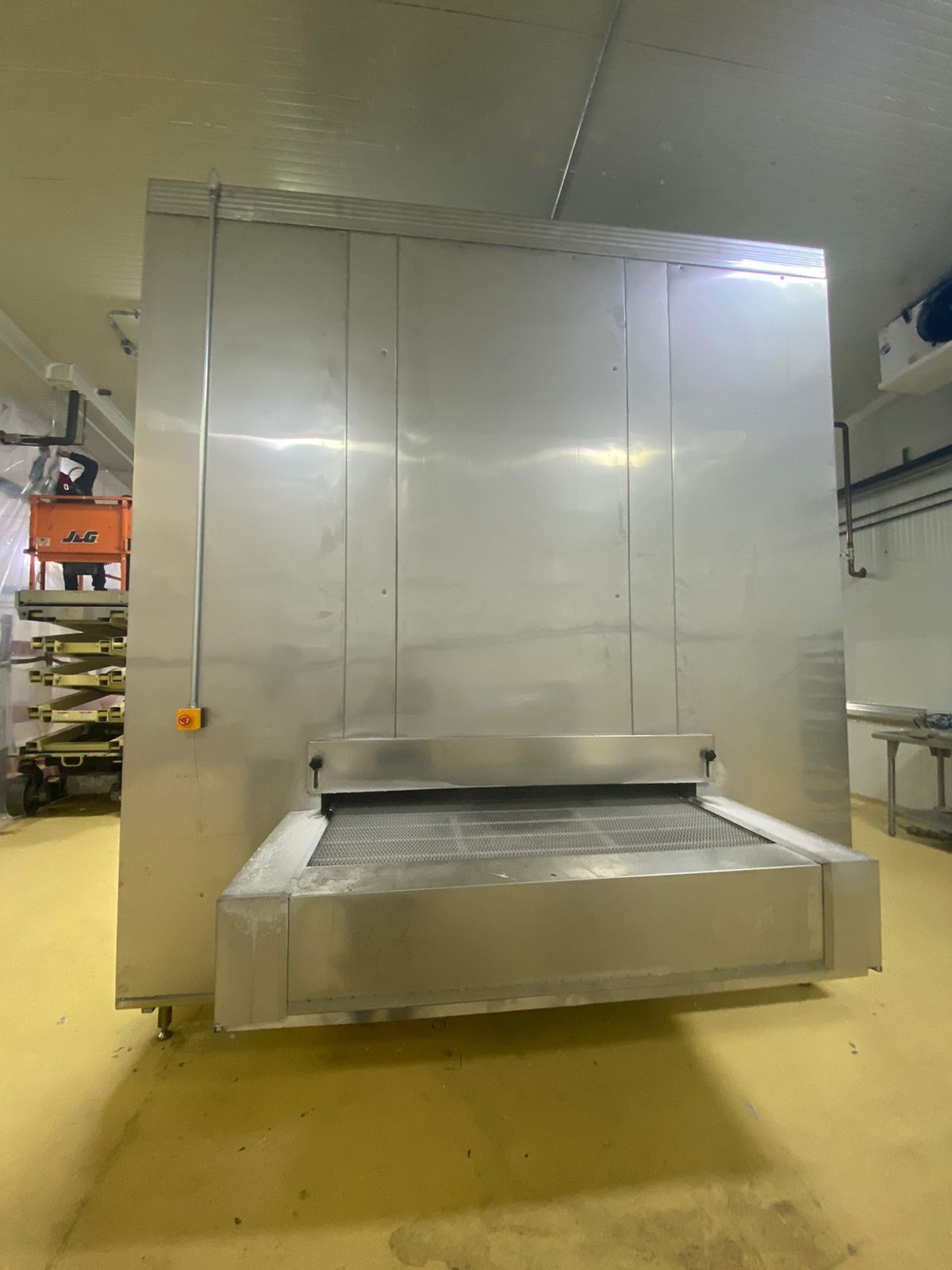

Why Choose impingement tunnel freezer

- Share

- Issue Time

- Mar 21,2022

Impact tunnel Freezer Body:

1. Freezer body based on the indoor assembled cold storage (ZBX99003-86), "combination refrigerator with heat insulation sandwich board" JB/T6527-2006 standard production, production, installation and acceptance. Library board adopts double stainless steel self-extinguishing flame retardant polyurethane sandwich

insulation board, panel thickness 0.8mm+0.5 mmSUS304 stainless steel plate, the plate thickness 150mm

2. Thermal insulation material, the plate adopts self-extinguishing flame retardant rigid polyurethane meet the following indicators: 40 kg/m3 density requirements or greater (less than a full board average density, then cutting sampling density); Coefficient of thermal conductivity is 0.024 w/m.k or less; Requirement: the compressive strength of the wall panel, roof is 150 ~ 200 Kpa, ground 300 Kpa or higher;

Bibulous rate is 4% or less; Dimensional stability < 1% (30 ℃, 48 h); Self-extinguishing 7 seconds or less.

3. Stainless steel plate with binding and firm, between the cohesive force between the two should be greater than 98.1 N/cm2, without cracking phenomenon. Use overall foam type, no per foliate pinhole, more than 30mm plane direction depth direction more than 10mm porosity, raw material, slag inclusion, burning core, influence the properties of heat insulation defects such as mixed waste phenomenon.

4. Library board adopts eccentric hook connection method, flat-fell seam to play four glue, process the hole or Angle of foam tank seam. Smooth, strong stability, tidy and beautiful, no warping, scratches and knock against, pollution, cold, and run the wind leakage phenomenon.

B ) Mechanical transmission:

1. Conveyor belt, chain network USES the food grade bright spring SUS304 stainless steel, with smooth surface, plate, wear shaft connected with flexible operation, large roller transmission chain net rolling;

2. Mesh belt and guide slide friction in contact area using high molecular wear-resisting PVC materials. Make guide slide friction is more reliable when in contact with the mesh belt and separation, not to drop crumbs, ensure the security of the

frozen goods.

3. Inlet platform fortification material ultra-high transfinite device, adjustable stainless steel wind insulation device; discharging mouth platform set up automatic blanking.

4. 4. The transmit driver using frequency conversion speed reducer, mesh belt running frequency control of motor speed, frozen time adjusted.

C ) Evaporator, and Defrosting:

1. Evaporator according to feed liquid evaporation temperature -42 ℃ design selection.

2. Evaporator using efficient is treated by surface oxidation rust from aluminum finned tube, to ensure uniform frost, air flow, bracket plate shell adopts stainless steel wind.

3. With high efficiency and energy saving, low noise axial flow fan, ram is stainless steel, it is anti-rust aluminum alloy blades, motor is fully enclosed moisture proof waterproof at low temperature, stable running.

4. adopts manual water defrosting method, water defrosting water spray device in evaporator, strong frost uniform, rapid, complete, water defrosting drain avoid ice blocking drainage and wind circulation, fortification water defrosting water splash.

D ) .Electric control:

1. All motors and power distribution cabinet external electrical components is not lower than IP55 protection grade, motor uses Y2 type waterproof.

2. Equipment, safety protection device is installed inside, can timely show abnormal of equipment operation, so that timely troubleshooting, import and export are equipped with an emergency stop device.

3. Electrical materials: the main control electrical components mainly adopts Schneider brand.