Why Choose First Cold Chain Spiral Freezer

- Share

- Issue Time

- Oct 10,2017

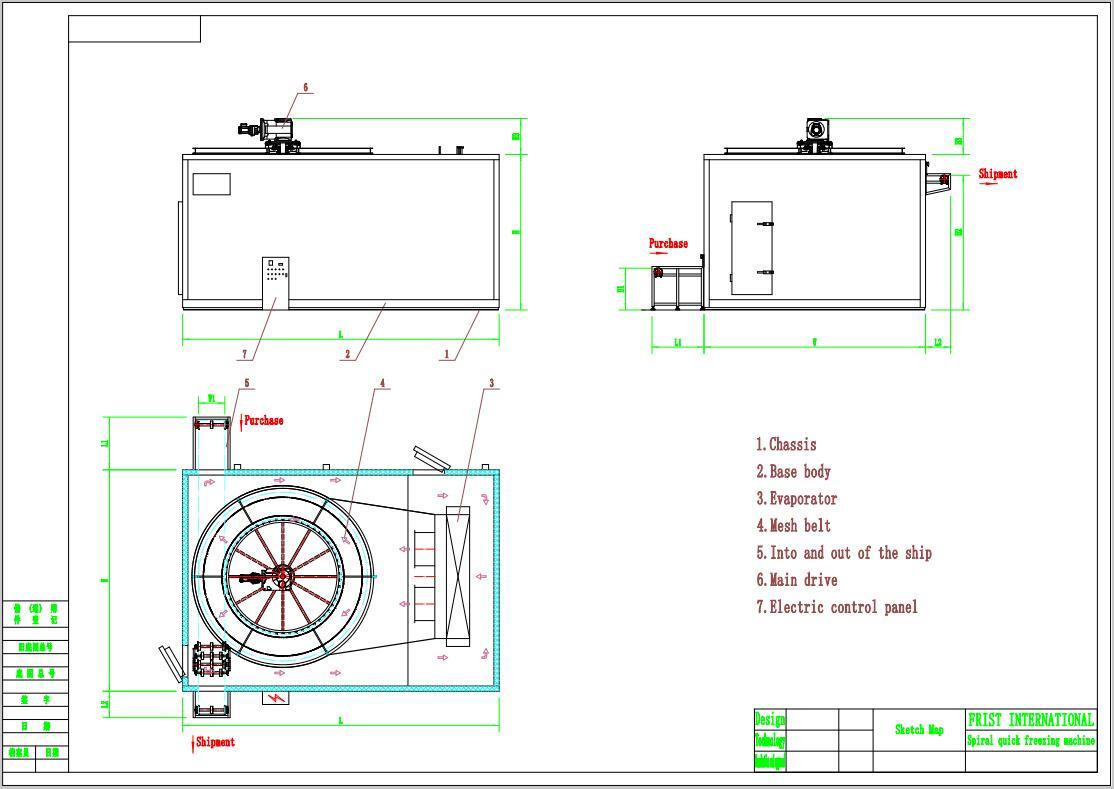

First cold chain spiral freezer overall advantage

1. Quick-frozen indoor clean and safe and reliable and energy saving

2. Restrictions on tape device, automatic fault alarm device, automatic stop device manually; Reliable operation running smoothly

3. Polyurethane insulation board; Duplex stainless steel anti-collision plate

4. Inside spiral freezer internal maintenance channel; the evaporator water defrosting device Facilitate cleaning maintenance

5. Inside spiral freezer within the whole welding stainless steel 304, and plate, side a sink, and avoid dust sleeper, ensure food safety and health.

6. Frozen zone frame structure, support, support, platform, air duct plate, mesh belt, skeleton, parts and components adopt food-grade SUS304 stainless steel (reducer, motor and other standard parts and special parts except).

7. In the reasonable air distribution ventilation, wind speed field and temperature field uniform stability, uniform freezing temperature;

8.With Outside transmission system , the equipment, reliable operation, energy saving, easy maintenance, in line with HACCP requirements.

9. Import and export parts designed to return by parts, stainless steel wind shield, shipment into bar insulation device, adjustable import and export of stainless steel wind heat preservation device, prevent different lead to two different temperature regions of the air pressure inside and outside air cold heat exchange cooling capacity loss.

10.The access door use SUS304 stainless steel double-sided self-extinguishing flame retardant rigid polyurethane insulation board, set safety electric heating devices, resistance to low temperature aging oil sealing strip, can open internally, accord with requirement of GB2894 safety warning signs, safe in operation.

11. Large effective special evaporator, the evaporation temperature and frozen indoor temperature difference is reduced, defrosting lag, defrosting independent drainage, separated from the cleaning water drainage, to facilitate defrosting water reuse.

12. Electric control

1. All motors and power distribution cabinet external electrical components is not lower than IP55 protection grade, motor uses Y2 type waterproof.

2. Equipment, safety protection device is installed inside, can timely show abnormal of equipment operation, so that timely troubleshooting, import and export are equipped with an emergency stop device.

3. Electrical materials: the main control electrical components mainly adopts Schneider brand.

4.According to the customers requirement offer PLC

Compressor unit

Compressor unit use well-know brand + company independent design and assembly, improve efficiency and prolong service life.