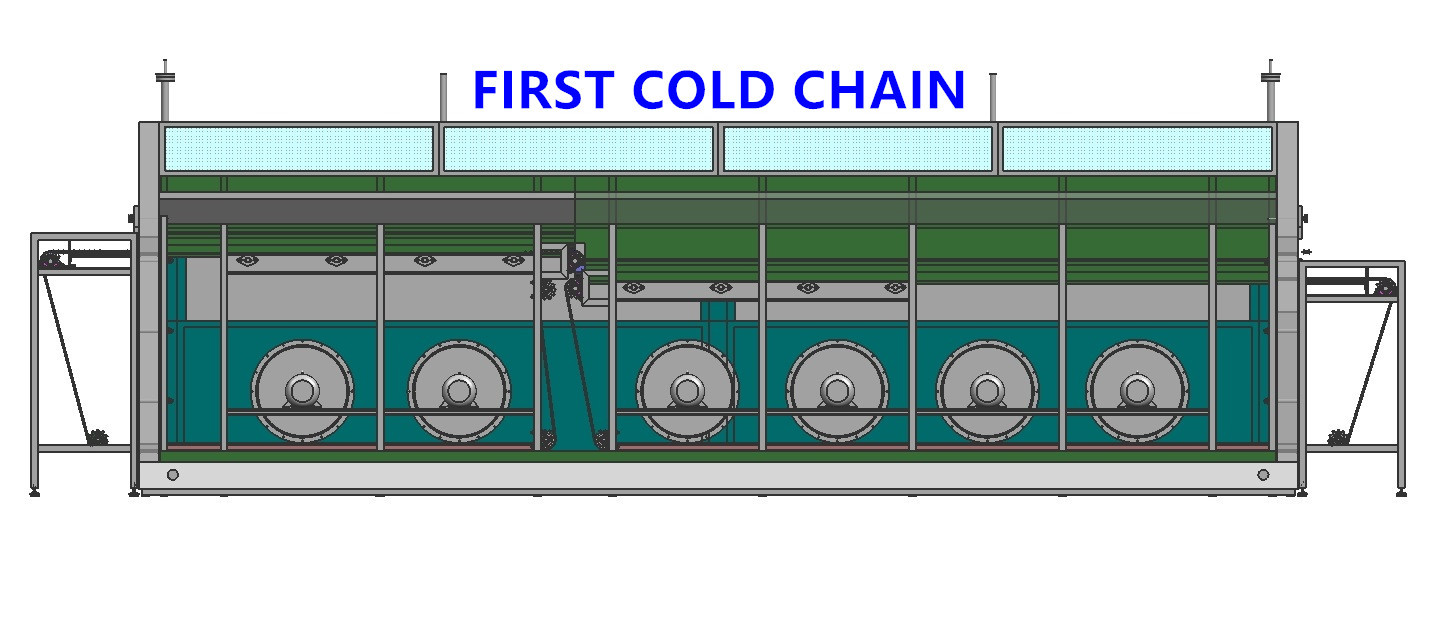

China first cold chain Fluidized IQF freezer for freeze blueberries/ professional IQF freezer

- Price

- US $90000-100000

- Model

- FSLD

- MOQ

- 1 set

Item specifics

- Refrigerant

- Freon

- Structure

- Assembled

- Suitable for

- Factory

- Refrigeration System

- Brand Compressor Unit

- Size

- Customized

- Use Nature

- Production

- Usage

- Vegetable & Fruit

- Freezer Body Material

- 304 Stainless Steel

- Specification

- CE ISO9001

- Transport Package

- Seaworthy Plywood Case

Review

Description

Fluidized IQF freezer Product Description

The best Fluidized IQF freezer for freeze all kinds of fruit & vegetable and some of the seafood

Working principle:

Working principle:

we have 2 kinds of freeze structure according to different product and capacity we adopt

1 stage or 2 stage freeze method:

Adopts the two stage belting structure

First, quick-cooling stage

Second, deep-freezing stage

Independently speed control system, and the speed of the two mesh belts can be changed infinitely

1. Quick-cooling stage: the food particles are to be quick cooled after entering into the blast room

The surface of the particles would frozen and reach the temperature of 0°C

Meanwhile, with the help of the striking chain, the particles would neither stick together nor sticker on the stainless steel mesh belt

2.Deep-freezing stage: food is to be moved on a stainless steel mesh belt, the foodstuff layer loosens with the increasing of the airflow

Some of the foodstuff particles become floating(this is the reason why this equipment is not applicable to big bulk foodstuff) when the air pressure reaches a certain scale, which brings interspace among the foodstuff particles, that is the way the fluidized bed come into being

The floating particles frozen quickly and individually because they are blowing with strong cool air from all directions

Adopts the two stage belting structure

First, quick-cooling stage

Second, deep-freezing stage

Independently speed control system, and the speed of the two mesh belts can be changed infinitely

1. Quick-cooling stage: the food particles are to be quick cooled after entering into the blast room

The surface of the particles would frozen and reach the temperature of 0°C

Meanwhile, with the help of the striking chain, the particles would neither stick together nor sticker on the stainless steel mesh belt

2.Deep-freezing stage: food is to be moved on a stainless steel mesh belt, the foodstuff layer loosens with the increasing of the airflow

Some of the foodstuff particles become floating(this is the reason why this equipment is not applicable to big bulk foodstuff) when the air pressure reaches a certain scale, which brings interspace among the foodstuff particles, that is the way the fluidized bed come into being

The floating particles frozen quickly and individually because they are blowing with strong cool air from all directions

Fluidized IQF freezer Parameters:

Mode | FSLD500 | FSLD1000 | FSLD1500 | FSLD2000 | FSLD3000 |

|---|---|---|---|---|---|

Throughput±10%(kg/h) | 500 | 1000 | 1500 | 2000 | 3000 |

Refrigeration capacity (kw/h) | 90 | 170 | 255 | 320 | 480 |

Freezer room size | 5×4.0×2.9 | 9*4.0*2.9 | 12×4.2×2.9 | 15×4.2×2.9 | 19×4.2×2.9 |

Exterior size | 7×4.0×2.9 | 11×4.0×2.9 | 14×4.2×2.9 | 17×4.2×2.9 | 21×4.2×2.9 |

Power(Kw) | 19 | 35.2 | 49.2 | 61.2 | 78 |

In feed temperature | +15℃ | +15℃ | +15℃ | +15℃ | +15℃ |

Out feed temperature | -18℃ | -18℃ | -18℃ | -18℃ | -18℃ |

Inner circulation temperature | -35±2℃ | -35±2℃ | -35±2℃ | -35±2℃ | -35±2℃ |

Frozen time(Min) | 6-30 | 6-30 | 6-30 | 6-30 | 6-30 |

Refrigerant | R717/R404A | R404A/R717 | R404A/R717 | R404A/R717 | R404A/R717 |