Revolutionize Your Business with Fluidized IQF Freezer for IQF Fruit and Vegetable Processing

- Price

- US $60000-200000

- Model

- FSLD

- MOQ

- 1 set

Item specifics

- Refrigerant

- Freon

- Structure

- Assembled

- Suitable for

- Factory

- Refrigeration System

- Brand Compressor Unit

- Size

- Customized

- Use Nature

- Production

- Usage

- Vegetable & Fruit

- Freezer Body Material

- 304 Stainless Steel

- Specification

- CE ISO9001

- Transport Package

- Seaworthy Plywood Case

Review

Description

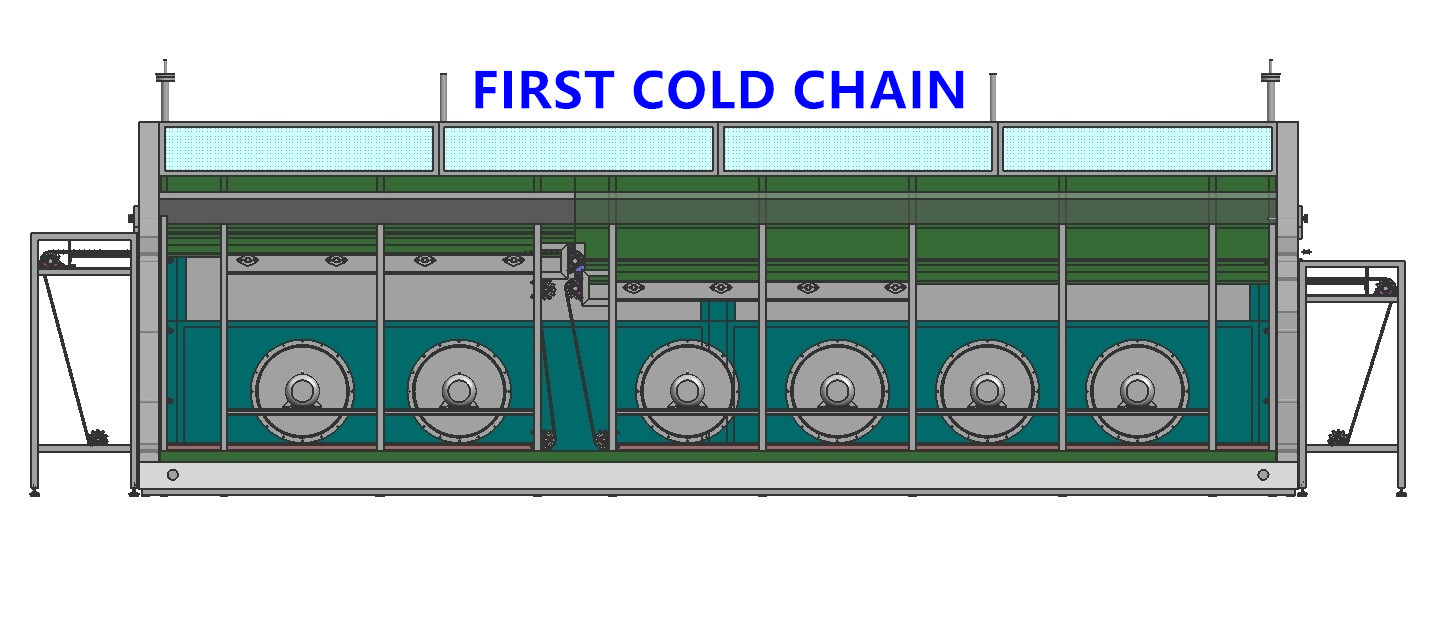

Fluidized IQF freezer Product Description

The FSLD series Fluidized IQF freezer adopts advanced technology, combines the latest design from Sweden and Canada, which increased the efficiency and quality for real individual quick freezing.

The Fluidized IQF freezer is the most suitable quick frozen equipment for vegetables, fruits such as peas, sweet corn, carrot slices or dices, caultiflower pieces, and etc. also it is very good for shrimps, seafood.

Generally it is very suitable for any food products with smaller sizes with big capacity need.

Main features of FSLD series Fluidized IQF tunnel freezer:

1) Designed according to HACCP requirements, which meet the international food hygienic standard.

2) Strong stainless steel frame and modular insulation board for freezer body.

3) High efficiency blowers with big air volume and high air pressure, well special design for fan blades for lighter weight to save energy.

4) Two section conveying belt to ensure the best fluidized quick freezing result.

5) Self made high quality aluminum evaporators with aluminum fins. High efficient and long working time.

6) High grade stainless steel spring wire mesh belt.

7) On position mesh belt cleaning device on the input area for easy cleaning during operation.

8) All detailed design and finishing to ensure the best quality of your final products.

Fluidized IQF freezer Parameters:

Mode

FSLD500

FSLD1000

FSLD1500

FSLD2000

FSLD3000

Throughput±10%(kg/h)

500

1000

1500

2000

3000

Refrigeration capacity (kw/h)

(To=-40, Tk=+35)

90

170

255

320

480

Freezer room size

L×W×H(M)

5.5×4.0×2.9

10*4.0*2.9

13×4.2×2.9

17×4.2×2.9

20×4.2×2.9

Exterior size

L×W×H(M)

7×4.0×2.9

11.5×4.0×2.9

14.5×4.2×2.9

18.5×4.2×2.9

21.5×4.2×2.9

Power(Kw)

19

35.2

49.2

61.2

78

In feed temperature

+15℃

+15℃

+15℃

+15℃

+15℃

Out feed temperature

-18℃

-18℃

-18℃

-18℃

-18℃

Inner circulation temperature

-35±2℃

-35±2℃

-35±2℃

-35±2℃

-35±2℃

Frozen time(Min)

6-30

6-30

6-30

6-30

6-30

Refrigerant

R717/R404A

R404A/R717

R404A/R717

R404A/R717

R404A/R717

Mode | FSLD500 | FSLD1000 | FSLD1500 | FSLD2000 | FSLD3000 |

|---|---|---|---|---|---|

Throughput±10%(kg/h) | 500 | 1000 | 1500 | 2000 | 3000 |

Refrigeration capacity (kw/h) | 90 | 170 | 255 | 320 | 480 |

Freezer room size | 5.5×4.0×2.9 | 10*4.0*2.9 | 13×4.2×2.9 | 17×4.2×2.9 | 20×4.2×2.9 |

Exterior size | 7×4.0×2.9 | 11.5×4.0×2.9 | 14.5×4.2×2.9 | 18.5×4.2×2.9 | 21.5×4.2×2.9 |

Power(Kw) | 19 | 35.2 | 49.2 | 61.2 | 78 |

In feed temperature | +15℃ | +15℃ | +15℃ | +15℃ | +15℃ |

Out feed temperature | -18℃ | -18℃ | -18℃ | -18℃ | -18℃ |

Inner circulation temperature | -35±2℃ | -35±2℃ | -35±2℃ | -35±2℃ | -35±2℃ |

Frozen time(Min) | 6-30 | 6-30 | 6-30 | 6-30 | 6-30 |

Refrigerant | R717/R404A | R404A/R717 | R404A/R717 | R404A/R717 | R404A/R717 |